IBC Tanks | IBC Totes 1000 liter

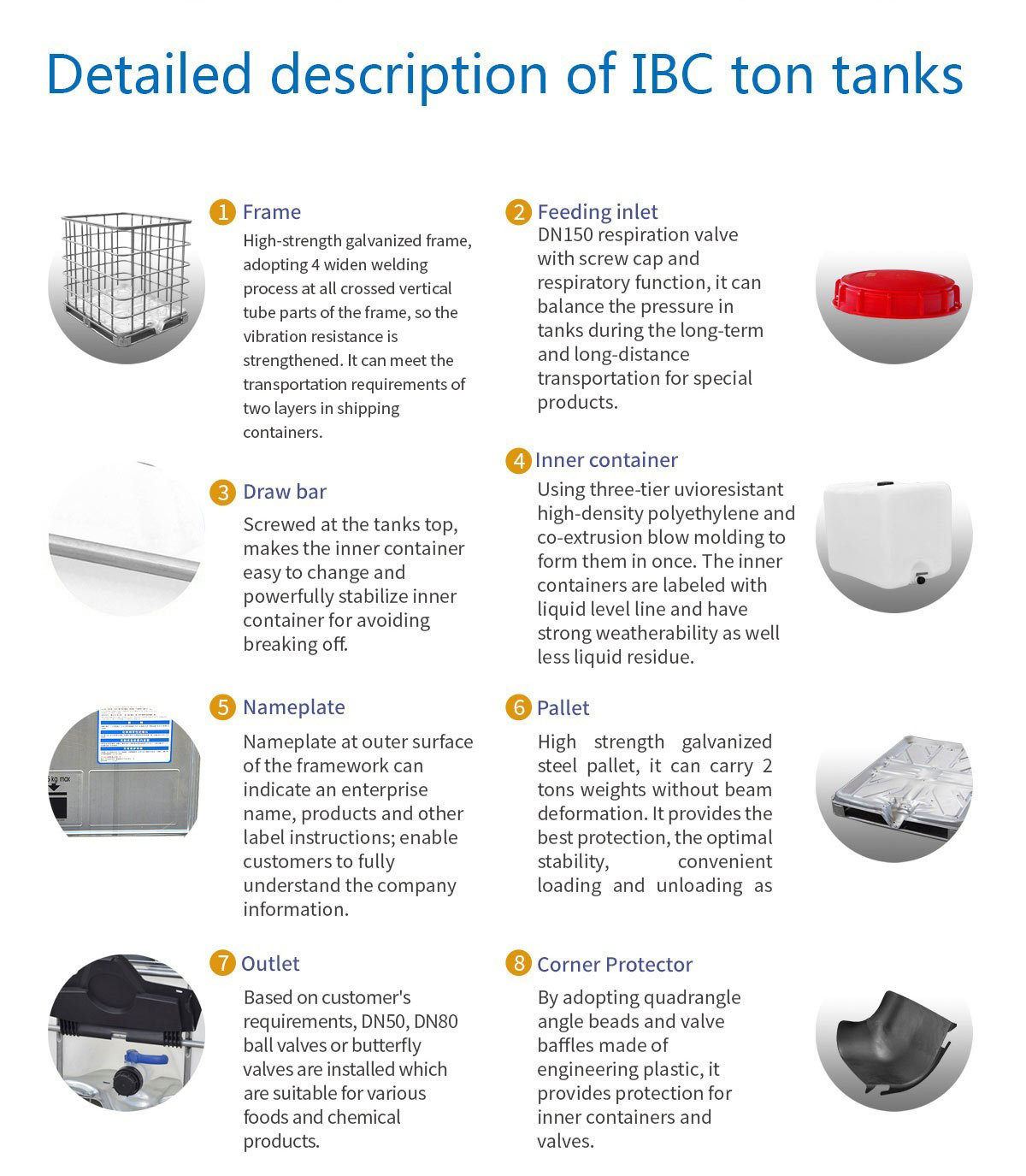

◆They are standardized design; convenient loading, unloading and transportation for mechanical equipment.

◆Made by blow molding from HDPE materials, it is characterized with high strength, easy to clean, non-toxic, tasteless, and acid and alkali resistance, strong weather resistance.

◆Made of high quality galvanized steel pipe, the steel frame is strong, durable and corrosion resistant.

◆Ventilation cover ensures the safety of the volatile liquid in transportation.

◆Enhanced valve plate and elastic angle bead have good performance in shock resistance.

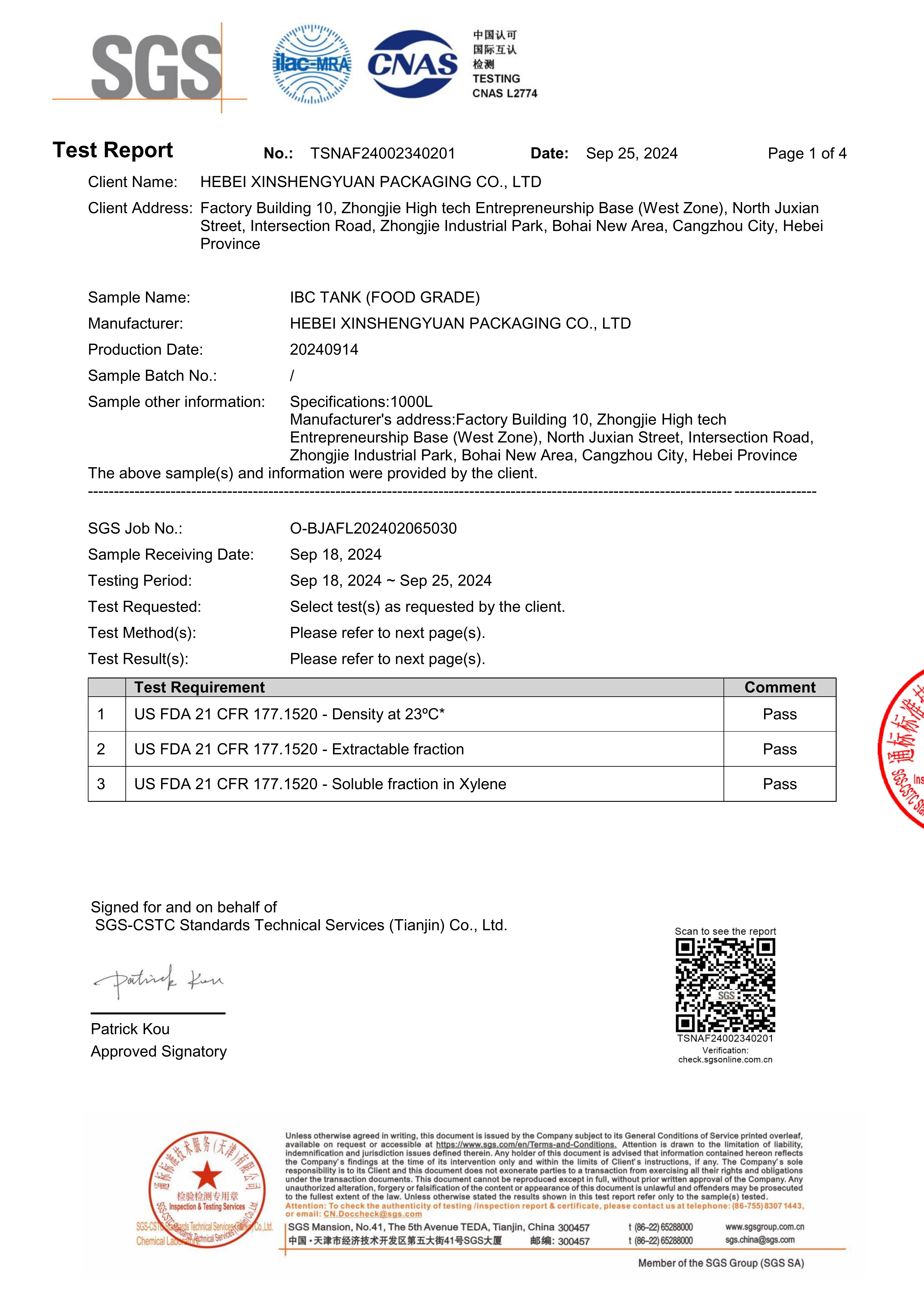

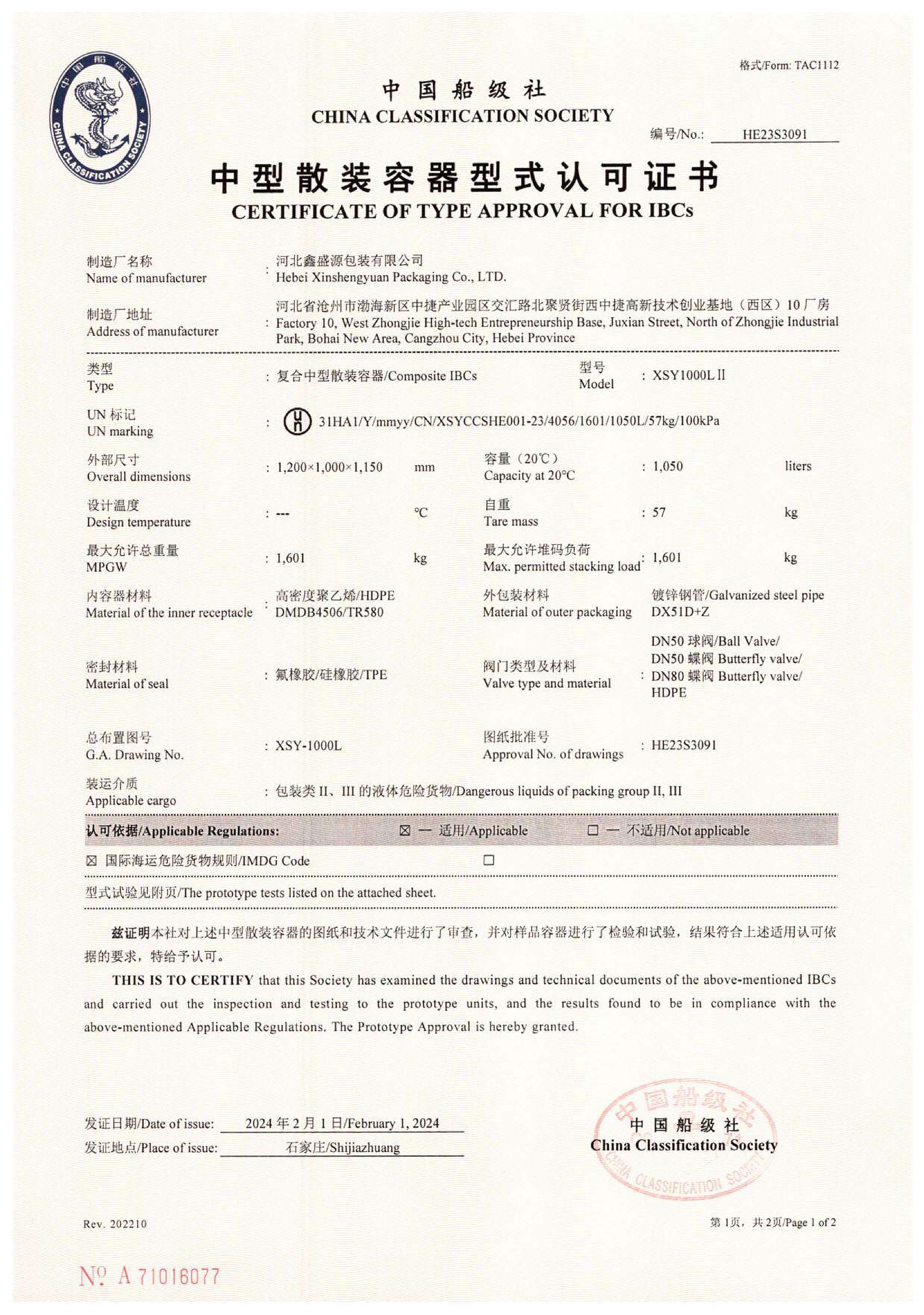

◆UN certification, CCSC and other certifications

◆FSSC22000 Food Safety System Certification

◆Modular design makes it easy to maintain and repair.

◆Can be stacked with other types of IBC ton tanks and recycled.

classification:

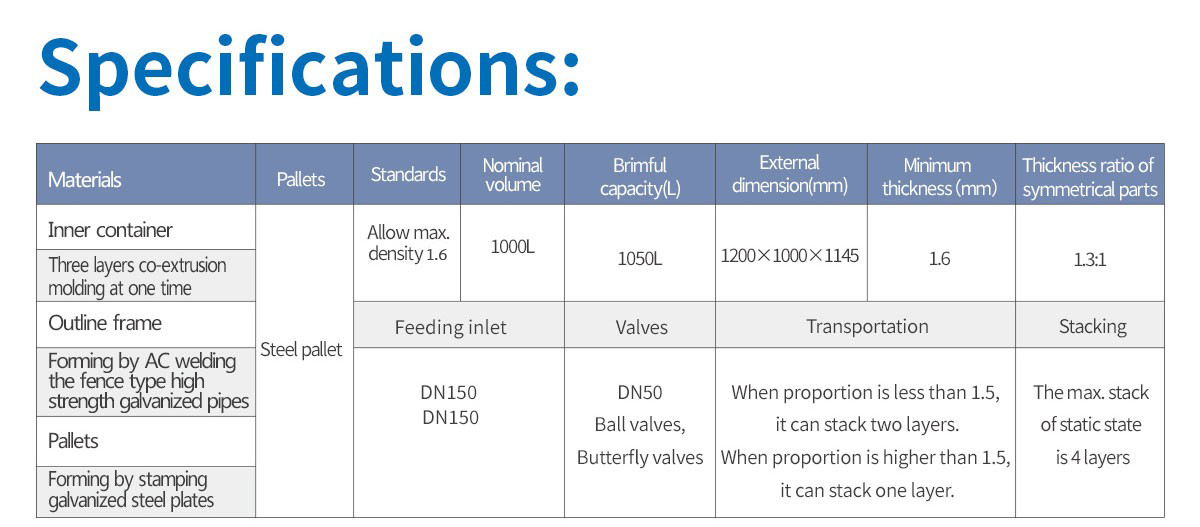

1000L Composite IBC Tank

seo:

IBC Tanks

1000 liter IBC

IBC 1000

IBC Totes

ibc for sale

ibc totes for sale

find ibc near me

find ibc totes for sale

ibc totes for sale near me

ibc totes for sale faqs

how to modify ibc tank

ibc totes sale

ibc container chemical

ibc tank chemical industry

ibc tanks in chemical

ibc tanks chemical

ibc tanks food grade

transportation of ibc totes

Product Details

Related Products