6L PLASTIC JERRY CAN

classification:

Plastic container

seo:

plastic jerrycan

jerry can

plastic container

water container

Product Details

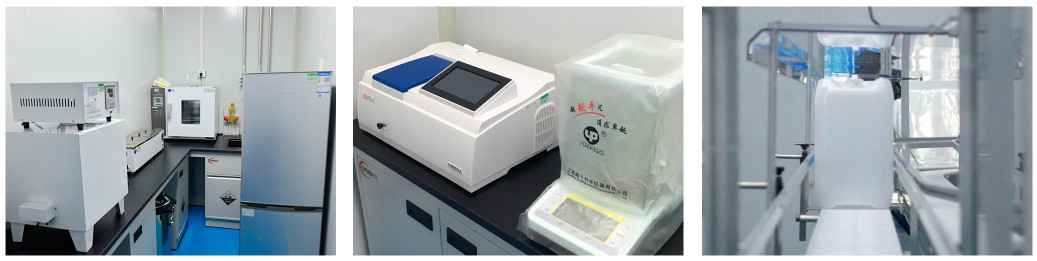

The main control console of the centralized feeding system strictly adjusts the flow rate and proportion of the raw materials in the inner and outer layers according to the set parameters.

With the HQ screw series, it exceeds the extrusion capacity of the peer by more than 30%, precise production control, small product weight fluctuations during the production process, and multi-layer co-extrusion process.

Adopt a blow molding machine with a forced feeding trough, multiple safety pressure protection devices, and more than 50 years of experience in multi-layer co-extrusion.

Accurate detection of particulate pollution and microbial limits.

Specifications | Weight | Maximum Diameter | Height | Mouth Diameter | Color |

6L Plastic Jerry can | 0.2(KG) | 189×147(mm) | 313(mm) | 35(mm) | White/Blue |

Packaging materialsBiocompatibility

☆The barrel body and lid material meet the biocompatibility requirements of China and the world (ISO 10993 series or GB/T 16886 series) to avoid toxin contamination concentrate and ensure the safety of dialysis treatment for patients

☆Microbial pollution control: the total number of aerobic bacteria shall not exceed 50CFU/barrel, the total number of molds and yeasts shall not exceed 50CFU/barrel, Escherichia coli, Staphylococcus aureus, Pseudomonas aeruginosa shall not be detected

☆Particle control: ≥ 10μm particles are not more than 6/ml; ≥ 25 μm particles are not larger than 1 / ml

last page

Next page

last page

Next page

Related Products