10

2025

-

04

What Are IBC Tanks Used For? A Comprehensive Guide to Their Versatile Applications

Intermediate Bulk Containers (IBC tanks) have become indispensable across industries for their efficiency, durability, and compliance with global safety standards. Designed to store and transport liquids, semi-solids, and granulated materials, these cube-shaped containers are UN-certified and built to withstand rigorous handling. In this article, we’ll explore the diverse applications of IBC tanks, their design advantages, and why they are a cornerstone of modern logistics and industrial processes.

1. Core Uses of IBC Tanks

IBC tanks are engineered for versatility, making them suitable for a wide range of industries:

A. IBC tanks used for Chemical and Petrochemical Industries

IBC tanks are widely used to handle hazardous and non-hazardous chemicals, solvents, acids, and lubricants. Their corrosion-resistant materials—such as high-density polyethylene (HDPE) or stainless steel—ensure safe storage and transport of aggressive substances. For example, stainless steel IBC tanks are ideal for flammable materials due to their heat resistance and compliance with NFPA 30 standards.

B. IBC tanks used for Agriculture and Water Treatment

Farmers rely on IBC tanks to store fertilizers, pesticides, and liquid feed. Their UV-stabilized HDPE construction protects contents from sunlight degradation, while food-grade options are used for potable water storage and irrigation systems. Water treatment facilities also utilize IBC tanks for chemicals like chlorine or pH-adjusting agents.

C.IBC tanks used for Food and Beverage Production

Food-grade IBC tanks meet FDA certifications, making them safe for transporting syrups, edible oils, wines, and dairy products. Wide-mouth models facilitate easy cleaning and mixing, while hygiene in breweries and distilleries.

D. IBC tanks used for Pharmaceuticals and Cosmetics

In pharmaceutical manufacturing, IBC tanks store raw materials, intermediates, and sanitized liquids. Their airtight seals and contamination-resistant designs align with strict industry regulations. Similarly, cosmetic producers use them for fragrances, lotions, and raw ingredients.

E. IBC tanks used for Architectural Paints and Coatings

IBC tanks transport adhesives, paints, and coatings efficiently. Their stackable design optimizes warehouse space, while integrated forklift channels simplify handling on job sites. Heavy-duty models with sloped bottoms ensure complete drainage, reducing waste.

F. Others

Can be used as a breeding space for fish species, convenient for changing water and observation; Can be used as a septic tank to produce biogas; Marinate seaweed, etc.

If you are using it for personal purposes, it is recommended to buy used ibc tanks, as this will result in a cheaper price. Just need to clean it a little and it can be used, but before cleaning the ibc tanks, it is necessary to ask what liquid has been filled before.

2. Design Features Driving Their Popularity

IBC tanks excel due to their innovative engineering:

Durability: Constructed from HDPE, stainless steel, or carbon steel, they resist impacts, punctures, and corrosive substances.

Compliance: UN/DOT certifications ensure safe transport of hazardous materials, including Packing Group II and III substances.

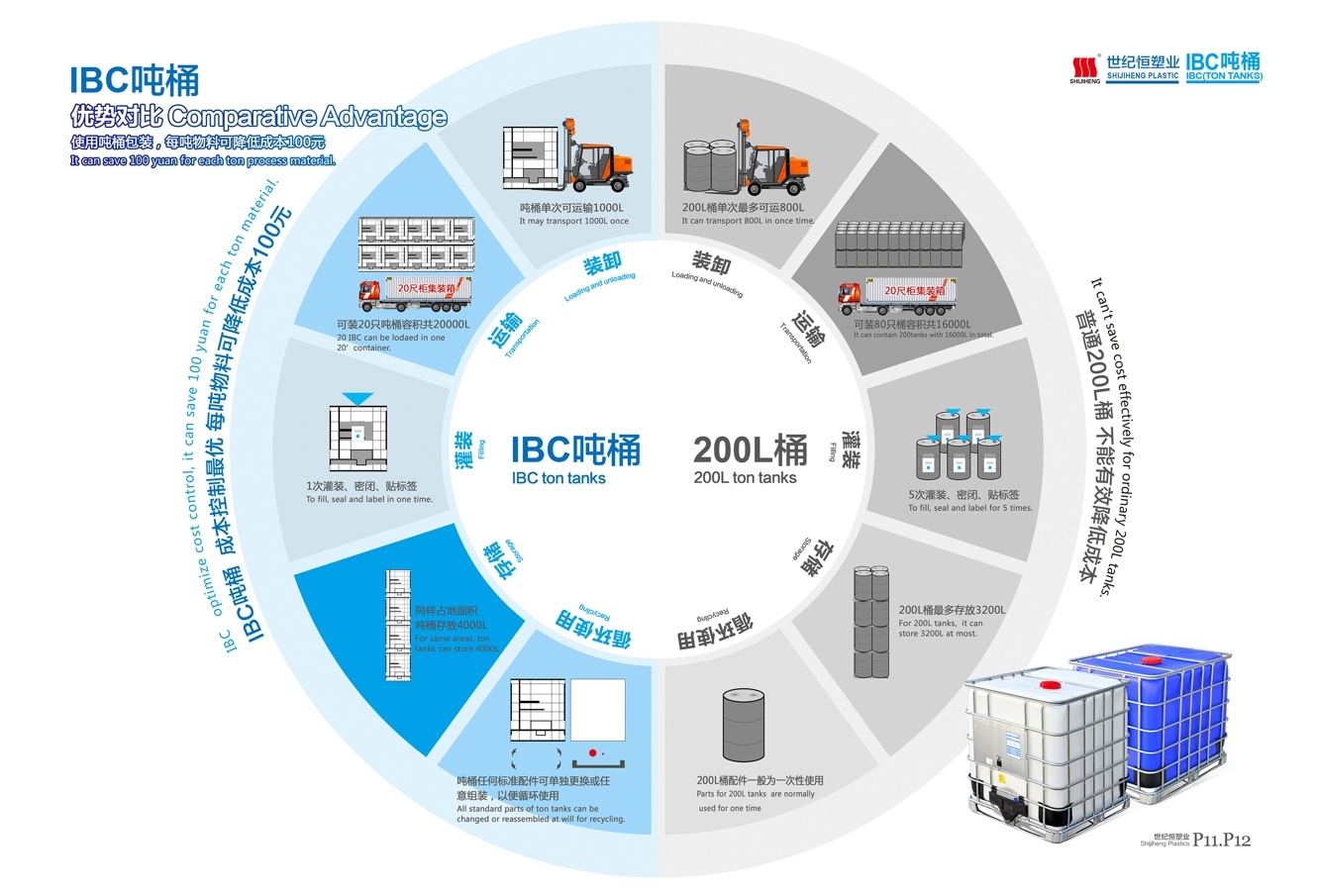

Efficiency: A single 270-gallon IBC tanks replaces five 55-gallon drums, cutting handling costs and reducing packaging waste.

Mobility: Integrated pallet bases and four-way forklift access enable seamless logistics.

3. Specialized IBC Tank Variants

Manufacturers offer tailored solutions for niche applications:

Caged IBC tanks: Steel-framed HDPE tanks for heavy materials like oils and industrial solvents. These are often single-use and recyclable.

Stackable IBC tanks: Rotomolded HDPE containers with reinforced bases for long-term storage of corrosives.

Stainless Steel IBC tanks: Used in high-temperature environments or for ultra-hygienic processes, such as pharmaceutical compounding.

If you want to know the types of ibc tanks, please click here.

4. Sustainability and Cost Savings

Reusable IBC tanks reduce environmental impact by minimizing single-use packaging. Many models withstand hundreds of trips, lowering long-term costs for businesses. For instance, reconditioned IBC tanks are cleaned and recertified, offering budget-friendly alternatives.

From safeguarding hazardous chemicals to streamlining food production, IBC tanks are a linchpin of modern industry. Their adaptability, compliance with safety standards, and cost-efficiency make them a smart investment for businesses aiming to optimize logistics and reduce waste. As sustainability becomes a priority, the role of IBC tanks will only expand, solidifying their place in global supply chains.

what are ibc tanks used for,ibc used for,ibc used