hdpe container

21

2025

-

03

How to Cut Open an IBC Tank: A Step-by-Step Guide for Safe and Efficient Modifications

How to Cut Open an IBC Tank: A Step-by-Step Guide for Safe and Efficient Modifications

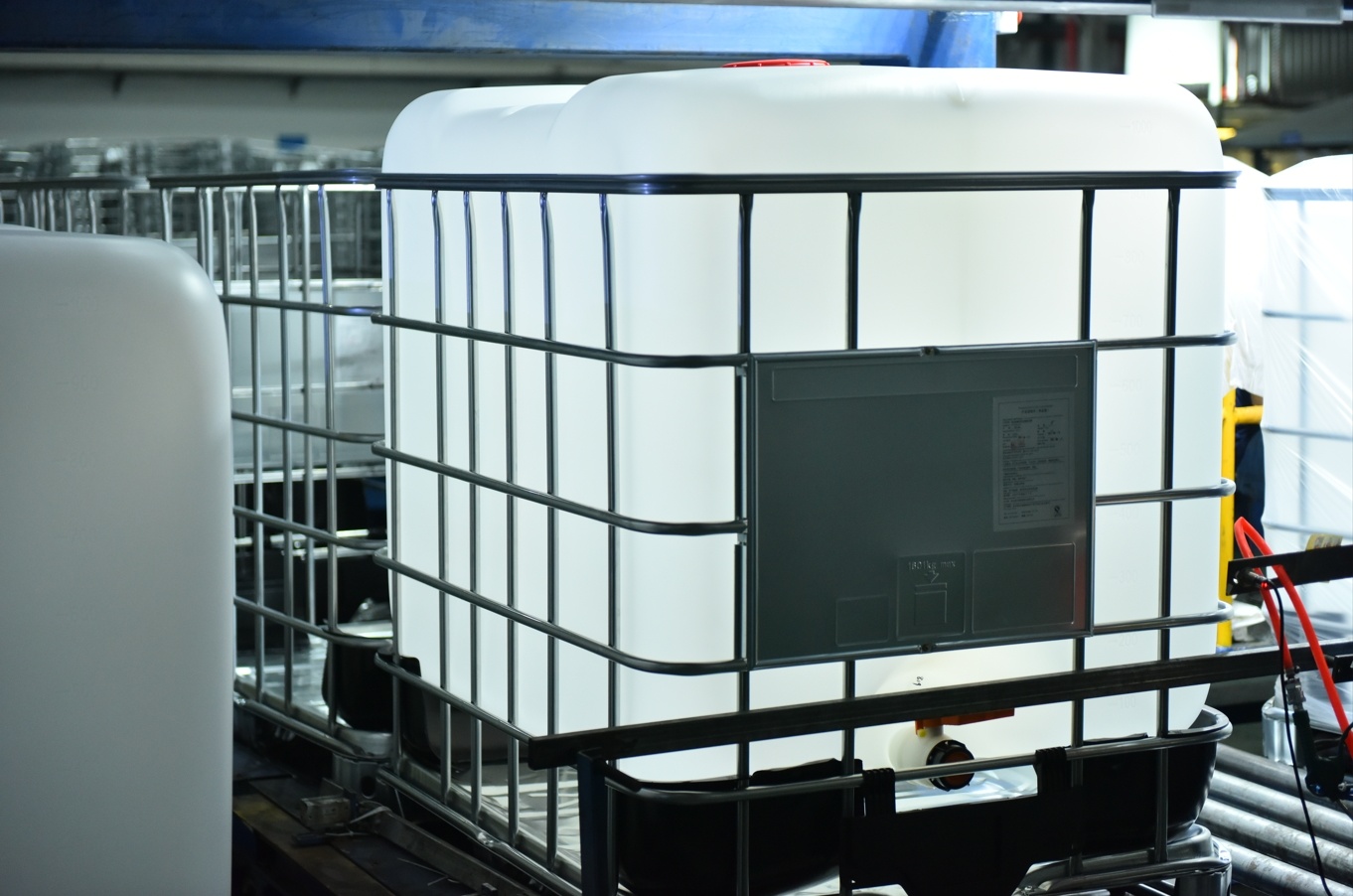

If you’re repurposing an Intermediate Bulk Container (IBC) tank for DIY projects, gardening, or industrial use, cutting it open safely is crucial. IBC tanks are durable, versatile containers, but their composite design—typically featuring a high-density polyethylene (HDPE) inner tank, steel cage, and pallet base—requires careful handling during modification. Below, we’ll walk through the process of cutting open an IBC tank while adhering to safety protocols and maximizing utility.

Understanding IBC Tank Structure

Before cutting, familiarize yourself with the IBC tank’s components:

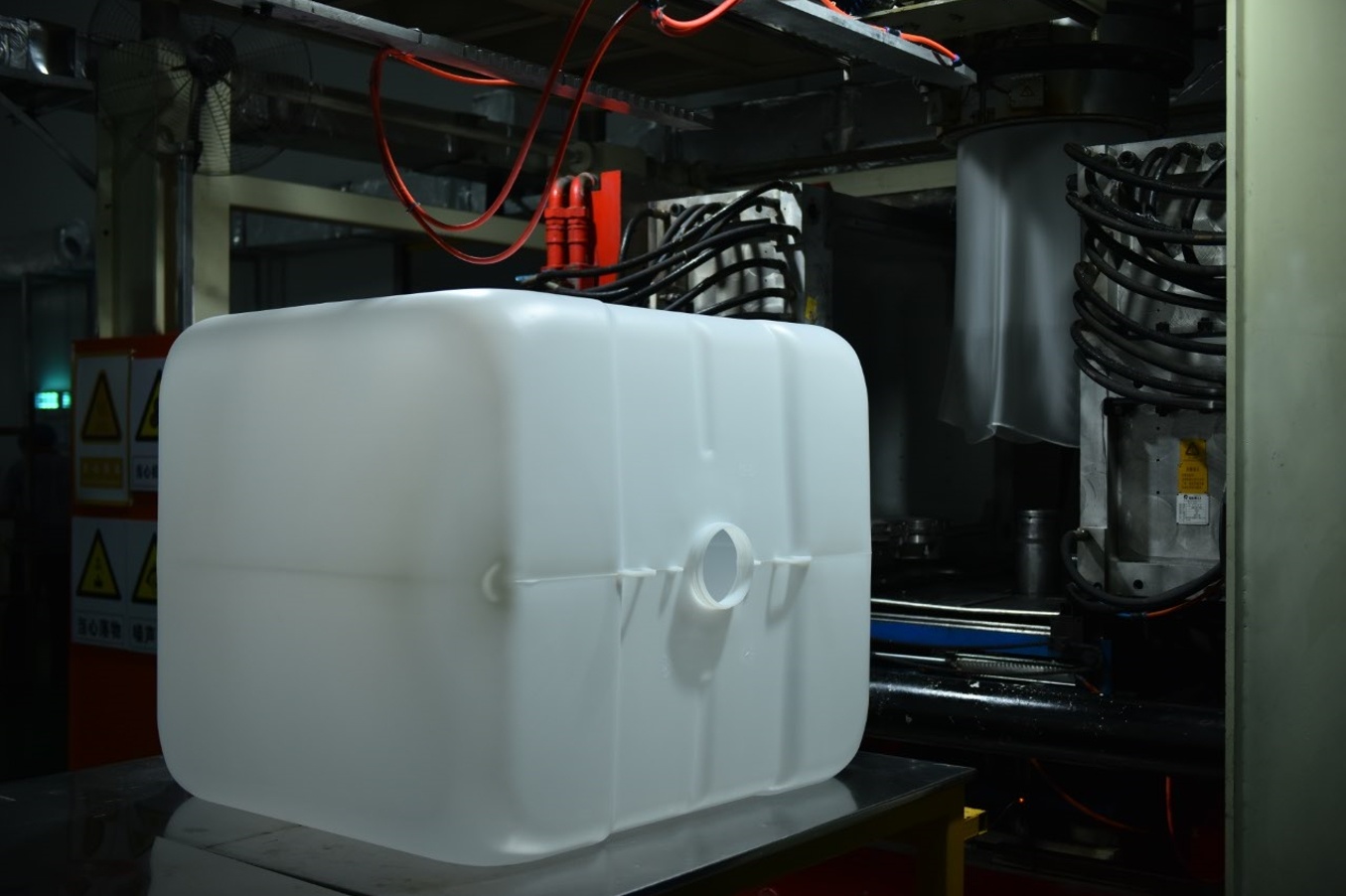

Inner HDPE Container: Corrosion-resistant plastic designed to hold liquids (1,000L nominal capacity).

Steel Cage: Protective outer frame for structural integrity.

Pallet Base: Facilitates forklift handling.

Valves and Openings: Includes filling (150mm) and discharge (50mm) ports, often with safety features like exhaust valves.

Step-by-Step Guide to Cutting an IBC Tank

1. Prepare the Tank

Empty and Clean: Ensure the tank is completely drained of any residual liquids. For tanks that previously held chemicals, rinse thoroughly with water and neutralize residues if necessary.

Remove Attachments: Detach valves, caps, or hoses from the filling and discharge openings.

2. Disassemble the Steel Cage

Use a wrench or angle grinder to remove bolts securing the steel frame.

Carefully lift or unbolt the cage from the pallet base to isolate the HDPE inner container.

3. Mark Cutting Lines

Plan your cuts based on the intended use (e.g., creating a large opening for a planter or storage). Use a marker to outline the area.

Avoid cutting near structural seams or stress points to maintain stability.

4. Cut the HDPE Inner Tank

Tools Required: A jigsaw, reciprocating saw, or circular saw with a fine-toothed blade optimized for plastic.

Safety Tip: Wear gloves, goggles, and a respirator to avoid inhaling plastic particles.

Technique: Cut slowly along the marked lines to prevent cracking or melting the HDPE.

5. Smooth Edges

Use sandpaper or a deburring tool to remove sharp edges from cut surfaces. This prevents injuries and ensures a clean finish.

Safety Considerations

Ventilation: Cutting HDPE can release fumes—work in a well-ventilated area.

Fire Risk: Avoid sparks near the steel cage; use non-abrasive tools if the tank previously held flammable substances.

Chemical Residues: Test for hazardous remnants if repurposing a used industrial tank.

Creative Uses for Cut IBC Tanks

Gardening: Convert the HDPE container into raised beds, compost bins, or rainwater harvesters.

Storage: Create custom shelving or tool organizers using the steel frame.

DIY Projects: Build furniture, animal feeders, or emergency water reserves.

FAQs

Q: Can I reuse the steel cage after cutting?

A: Yes! The cage can be repurposed for structural support in construction or gardening projects.

Q: How do I ensure a leak-proof seal after cutting?

A: Use HDPE welding rods or food-grade silicone sealant to reinforce seams.

Q: Is specialized equipment needed for cutting?

A: Standard power tools work, but blades designed for plastics yield cleaner results.

how to modify IBC tank,How to Cut Open an IBC Tank,cut ibc tank,cutting HDPE containers,IBC tank repurposing ideas